International

projects

ADVANCED DESKTOP METAL 3D PRINTER BASED ON BINDER JETTING. BJET

Description: The overall goal of the project is to develop an advanced desktop 3D printer capable of creating metal parts for end-use, focusing on strength and cost-effectiveness. Additionally, the development of a binder that can make the sintering process of printed parts easier and safer.

Geographical or thematic scope of the project: International project focused on the topic of Additive Manufacturing.

Project timeline:

Start date: 07/2021

End date: 12/2024

Investment: €600,735.00

EU Grant: €509,999.99

Motto: Europe feels

Results:

- Development of 3 prototypes of 3D printers, leading to the final machine.

- Development of a new water-based binder for use in different Binder Jetting printers.

- Development of post-processing systems for Binder Jetting technology.

EVAM®

A genetic algorithm for time optimization.

EVAM® II ADDITIVE MANUFACTURING AUTOMATION AND OPTIMIZATION SOFTWARE

The reduction of machine downtimes in an environment of parallel identical machines is well known in the theory of computational complexity as “NP-Hard (Nondeterministic Polynomial time)”, normally a deterministic solution for this type of problem is not usually found.

After an exhaustive R&D phase in heuristic methods, at TRIDITIVE we have managed to develop a genetic algorithm that allows us to plan the jobs according to the most important parameter in additive manufacturing, the earliest date of delivery of a production order ( EDD. Earliest Due Date), known in programming theory as the earliest due date rule, which minimizes the maximum delay on a single machine.

BULKAM®

The challenge of large additive manufacturing.

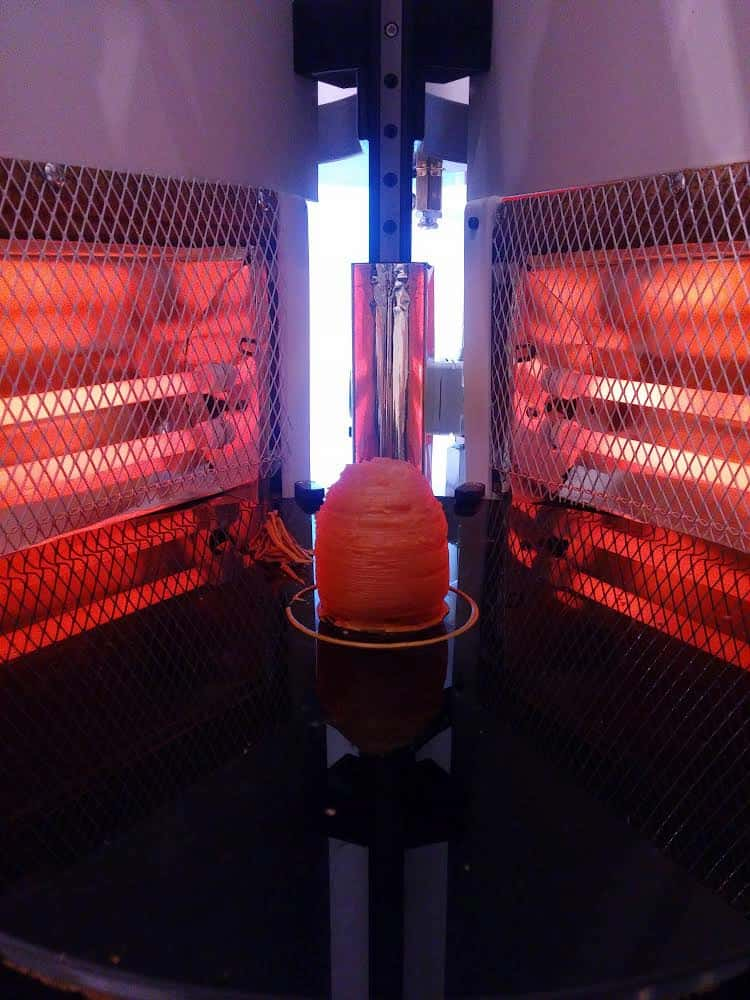

BULKAM

The aim of this project is to Design, Calculate, Build, Start Up and Validate the operation of a large 3D Printer prototype. The objective is to be able to satisfy the needs of the clients, currently not covered, in terms of 3D printing of larger pieces, ensuring their quality as ha s been done so far in smaller pieces. One of the main challenges in the design and construction of a large printer is the mechanical analysis of the stresses to which the machine will be subjected, accelerations, optimization of the head weight to avoid resonances and defects in the final parts, chamber temperature control and finally the chamber temperature control software.

Each and every one of these variables will be taken into account when designing a globally functional team. Next, the printer will be built, validating its operation as well as the properties of the parts that are manufactured in it.

Finally, depending on the results obtained, the most convenient formulas for their exploitation will be analyzed, defining the corresponding protection protocols.

Goals

The main objective of this project is to design, calculate, build and validate the operation of a large 3D printer prototype. To do this, the following secondary purposes will have to be achieved:

- Design the 3D Printer model.

- Study the structural behaviour of the Printer.

- Develop a specific print head to supply larger amounts of print material.

INKAP 3D

New ways of using the additive manufacturing technique for 3D printing of functional foods

INKAP 3D

In this project, new ways of using the additive manufacturing technique for 3D printing of functional foods through in situ microencapsulation of probiotics will be investigated, as well as the different food inks that would be necessary to print the food. The main challenges facing this project range from the characterization and properties of the type of material to be printed, through the design of the print heads, temperature control and conditions for printing, to the development of precision software for print the type of encapsulated food. Each and every one of these variables will be taken into account when designing a globally functional prototype.Goals

It is a project that has three clearly identified objectives:

- Identification, characterization and validation of functional foods produced using the 3D printing encapsulation system.

- Development of new food printing inks both those that will make up the food and those that will serve as wall material for the microcapsule that will contain the active compound.

- Design, calculation, manufacture and commissioning of a 3D printer prototype for the production of functional foods.

TRACED®

AMBROAD

SPREAD

METALAM

BRANDING

SCALADD

ESCUADRAS

Transition towards the circular economy and sustainability in the defense industry.

RIS3-EMPRESA (EBT-II)

EBT development and growth plan.

FLEXCELL

Flexible additive manufacturing cell for emergency events

3DPARTS

Technological consulting for the characterization and optimization and optimization of geometries and physical properties of prototypes of demonstrator parts prototype demonstrator parts manufactured by AMD® (Automated Multimaterial Deposition) additive manufacturing.